| 1908 |

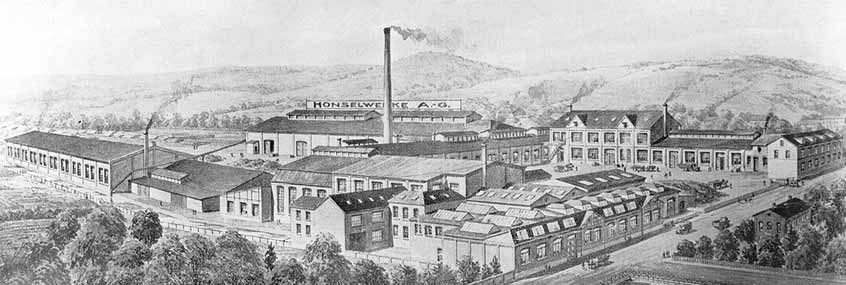

Fritz Honsel founds "Fritz-Honsel-Gravieranstalt und Formenmacherei" in Werdohl. It produces moulds for casting aluminium and cutlery in aluminium. |

| 1911 |

The first series fabrication of aluminium parts in permanent mould casting ramps up. |

| 1917 |

The plant in Meschede is built. |

| 1919 |

The plant in Meschede is expanded by a sheet metal mill and a permanent mould foundry. |

| 1925 |

With a major order for Opel’s "Laubfrosch" the foundation stone is laid for Honsel’s success story in the automotive industry. Engine components are manufactured in aluminium. |

| 1929 |

With the building of the die casting shop, the technology portfolio is extended by a new manufacturing method. |

| 1933 |

Honsel die-casts magnesium for the first time. In the first production series engine and transmission parts are cast. |

| 1941 |

Series production of cylinder heads and housings for aircraft engines ramps up. |

| 1958 |

The first extrusion plant is built in Meschede. |

| 1970s |

Honsel’s engineers develop a die-cast housing for bus transmissions from ZF. The first Daimler truck transmission housing is produced in permanent mould casting during the same decade. |

| 1973 |

The extrusion plant is opened in Soest near Meschede. |

| 1980s |

For Volvo, the company produces 4-, 5- and 6-cylinder engine blocks. |

| 1982 |

Honsel acquires the company Mönig in Nuttlar. This family business is specialized in tool and die making. With the purchase, Honsel expands its technology portfolio by a core module and becomes much less dependent on its suppliers. |

| 1989 |

Honsel goes onto the stock market. |

| 1995 |

With heat treatment of die cast parts, Honsel opens up new possibilities for the carmakers. The first heat-treated die-cast component is an integral carrier for Daimler. |

| 1995 |

Honsel continues to build up its capacities in Europe with the purchase of the die casting plant in Nuremberg and the laying of the foundation stone for the building of Fonderie Lorraine S.A.S. |

| 1999 |

The financial investor Carlyle Group buys the Honsel Group and begins building up Honsel International Technologies (HIT). |

| 2001 |

The production of V6 engine blocks for Daimler begins. |

| 2003 |

Together with Daimler, Honsel develops the magnesium housing for the new 7-speed automatic transmission. Without significantly more weight than the 5-speed automatic transmission used up to then, the E- and S-classes get two additional gears. |

| 2004 |

Honsel International Technologies is taken over by Ripplewood Holdings Japan International (RHJI). |

| 2005 |

Honsel delivers the Short I6 engine blocks and cylinder heads to Volvo almost ready to install. The production systems built up especially for them are a paramount example of increased manufacturing depth in the casting business. |

| 2007 |

The acquisition of Tafime is a clear signal that Honsel is pursuing its international direction rigorously. The sites in Spain, and especially in Mexico, strengthen its position as a global and dependable partner to its customers. |

| 2009 |

Honsel proves its innovative power yet again and successfully develops its own technology to manufacture engine blocks with coated cylinder linings. |

| 2011 |

Closing after insolvency accomplished: Martinrea International purchased the assets of the plants Meschede, Soest and Nuttlar through its new subsidiary Martinrea Honsel Germany GmbH. The plants in Spain, Mexico and Brazil are also aquired by other subsidiaries of Martinrea International. |